PROCESS

THE MANUFACTURING PROCESS OF FIBOPE® FILMS:

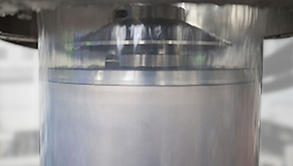

The transformation process of is called “DOUBLE BUBBLE”. The first phase is the extrusion of polymer in a descending direction through a multilayer die which forms a primary tube that is immediately cooled. The primary tube is then pulled to the top of the orientation tower, using a Pull Unit. At the top of the tower, the primary tube is drawn in a downward direction and, at the same time, it is heated to a temperature just below the melt point, supported by infra-red resistances. At the start-up, when this temperature is reached, air pressure is introduced expanding the tube to the gauge required. The biaxial orientation takes place as the tube is expanded and the downward speed is accelerated. After this operation, the bubble is collapsed between two sets of rollers. The resulting flat sheets are then cut and rewound onto master rolls.

SLITTING AND FOLDING

EXTRUSION

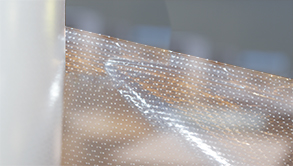

MARKED